Racks are used in the warehouses to keep things organized and make sure that there is plenty of free space for keeping goods. For making the systems work, selecting a proper racking system is very important for any business. Pallet racks, cantilever racks and mezzanine floors are some of the types of (racks) which store different products differently Selecting the perfect rack system allows businesses to make effective use of space and route their warehouse equipment in a streamlined manner. Moreover, racks also have a big impact on how inventory is handled in terms of whether they need to adhere to the rule: "First-In-First-Out", or "Last-In-First-Out"; which further expedites item-picking_PROCESS.

It is important to recognize that every company has unique storage needs. This would allow companies to receive unique rack solutions designed especially for them. Some such as cold-storage viewing racks to cater cleanliness and withstanding low temperatures at required humidity, others for e-commerce in providing quick order fulfilment etc. In order to equip a system that reduces costs as well as the potential for size extensions, it is important to be able identify what products has each company like dimensions of movement and weight.

The safety of stored items is a top concern especially with high value or perishable goods. Well-designed rack systems create a safe working environment, by keeping the stored goods secure against collapsing or falling over which could pose risk both to merchandise and employees in warehouses. Additional safety directives could be deployed like using seismic-resistant racks in earthquake zones or the use of wire decking for fire-safety enhancing overall security of stored goods. In addition, combining access control systems and CCTV cameras can help make warehouse break-ins less attractive to thieves and offer you eyes on your rack bays to guard against the theft of specialty or high value inventory.

Nowadays people increasingly talk about the relevance of sustainability in business. To help fulfill environment goals, some firms are choosing environmentally-friendly rack systems from utilizing recycled materials or disassembling and reusing. The best ways to reduce a company's carbon footprint are embracing solar-powered lighting in racks and switching energy-efficient storage systems that require less temperature regulation. In addition, modern rack systems provide space and improved capability to rapidly locate items in the warehouse.

To conclude, racks are the topmost instruments in the warehouse which affect how efficiently, safely and innovatively storage practices are carried out today. With the choice and production of horizontal systems adapted to each business need, companies can achieve higher productivity levels, ensure product safety take environmentally correct attitudes in their processes and use modern technologies for an advantage over competitors when digging into logistics/storage tasks. The first thing any warehouse operator will tell you is that the right rack system makes up half of being perfectly operational, and by extension prosperous in warehousing.

Efficient warehouse operations are the cornerstone of any successful business, and the right rack system is key to achieving this. Pallet racking, cantilever racks, drive-in/drive-thru systems, and mezzanine floors each serve unique purposes, catering to different product types, turnover rates, and floor space constraints. By carefully assessing inventory flow and storage density requirements, businesses can select a rack configuration that not only optimizes vertical space but also enhances material handling processes. Intelligent rack layouts facilitate the First-In-First-Out (FIFO) or Last-In-First-Out (LIFO) inventory management strategies, reducing pick times and increasing overall throughput.

No two businesses are alike, and thus, their storage needs vary greatly. Customized rack solutions allow for tailored storage that perfectly aligns with a company's operations. For instance, cold storage facilities require specialized racking designed to withstand low temperatures and humidity, while e-commerce retailers may benefit from carton flow or pick modules to facilitate rapid order fulfillment. Understanding the nuances of one's business, such as product dimensions, weight, and turnover frequency, is crucial in designing a rack system that streamlines operations, reduces costs, and accommodates future growth.

The safety and security of stored goods are paramount, especially when dealing with high-value items or perishable products. Robust racking systems with sturdy frames and bracing can prevent accidents like collapse or tip-over, protecting both merchandise and personnel. Implementing seismic-resistant racks in earthquake-prone areas or using wire decking to improve fire safety further bolsters security measures. Additionally, incorporating access control systems and surveillance cameras can deter theft and monitor rack zones, ensuring that sensitive or expensive stock remains well-guarded.

Sustainability has become a driving force behind many business decisions, including warehouse storage. Eco-friendly rack systems made from recycled materials or those designed for easy disassembly and reuse contribute to a company's green initiatives. Using solar-powered lighting within racks or opting for energy-efficient storage systems that reduce the need for constant temperature control can significantly cut down on carbon footprint. Moreover, dynamic storage solutions like automated retrieval systems minimize energy consumption by optimizing travel distances for forklifts, demonstrating that efficient storage can go hand in hand with environmental stewardship.

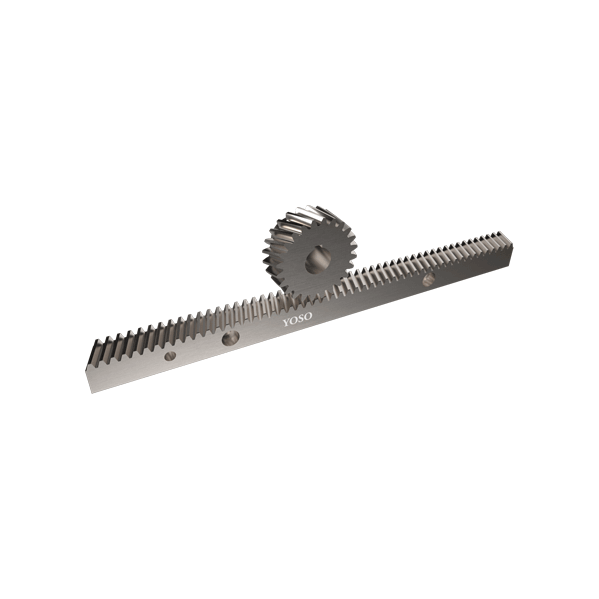

YOSO specializes rack all kinds mechanical transmissions. latest large-scale, 6-meter CNC production lines produce single six-meter rolling guides rails lots. maximum dimension guide rail 125. Guide rails offered full range comprising 25, 30 35 55, 65 85 100 125. maximum load capacity individual slider 192t. Screw production base capable producing batches least Ph6mm thickness lead 1mm maximum Ph245mm, length screw up 10m maximum dynamic load up 125 tonnes. It able provide two meters C1 level three meters C2 level batches , 5-meter C3 level, 10 meters C5 level various balls screw,YOSO Motion best linear system partner. work together you aid Industry 4.0.Subvert impression Made China.

Multi-product Integration rackYOSO We offer complete control transmission components One-stop-shop products meet requirementsour customers. We're committed helping clients compete in marketplace through providing technological solutions, factory efficiency, brand marketing power product quality.We offer product range wide selection superior performance have earned trust in market due our deep understanding customer requirements.Partners around world established closer relationships YOSO, and internationalization strategy YOSO brand dealers reach customers their regions through global network. Contact me you interested becoming involved!

Jingpeng Machinery founded 2015 is headquartered Shanghai; it officially launch EU branch Poland rack. Jingpeng Machinery continue increase global presence.In past 10 years, YOSO now fully integrated trade industry platform mechanical transmissions own trademark as well international patents. Jingpeng stuck corporate philosophy that centered "brand, service quality" right the beginning.YOSO a brand allows us take part international exhibitions industry year. Quality at heart rack's long-term development. Service makes customers business partners.Jingpeng Machinery become top purchasing platform industrial 4.0 mechanical transmissions. trust from 10 years flawless products, 190 experienced engineers, 24 modern manufacturing lines 50,000m2 production base; manufacturing each mechanical product requires dozens carefully chosen production processes, YOSO determined create perfect products.

Brand:10 Years International Exhibition ParticipationQuality is underlying principle sustainable developmentService: Customers partnersrack TransmissionYOSO has trained professionals the field transmissioncomponents within company perfectly analyzecustomer drawing requiremenis 3D finished productmodels facilitate production arrangements.Industry ExchangeYOSO fervent patron most well-known industry exhibitions held worldwide takes part them. exchanges betweenpractitioners forward-looking applicationentrepreneurship leading companies importantsoil our growth.

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved