Introduzione:

C'è un detto secondo cui l'innovazione è sempre stata la base dello sviluppo e della crescita in qualsiasi industria. L'industria manifatturiera ha visto grandi balzi avanti grazie all'introduzione di vari strumenti e macchine nel suo processo, rendendolo più semplice ed estremamente efficiente. Uno di questi strumenti è la vite a sfera del centro di lavorazione a gantry, che ha portato il settore a un livello completamente diverso, offrendo sicurezza e numerosi vantaggi che saranno un elisir per aziende e individui in molti modi.

Tra i numerosi vantaggi, la vite a sfera del centro di lavorazione a ponte è semplice e versatile, può assistere sia nella produzione di componenti facili che complessi. È uno strumento flessibile utilizzato nella produzione attraverso una varietà di prodotti, dimostrandosi quindi uno strumento affidabile per le attività commerciali che operano in diversi settori industriali. Ha anche un alto grado di precisione, quindi si può essere sicuri della fabbricazione di prodotti con specifiche esatte. Unendo a questo il fatto che la vite a sfera del centro di lavorazione a ponte è facile da usare, sta diventando sempre più lo strumento preferito tra tutti gli utenti, dai principianti agli avanzati.

La palla elicoidale del centro di lavorazione a gru è una delle macchine più ingegnose mai inventate e, infatti, ha cambiato il volto dell'industria manifatturiera. Mette in pratica una tecnologia avanzata che garantisce risultati eccellenti nella produzione di prodotti e rende il processo efficace per la produzione di massa. Possiede anche alcune impostazioni che possono essere regolate secondo le proprie esigenze di produzione individuali. Ha capacità avanzate che possono portare la produttività al passo successivo desiderato dai produttori.

Il bullone a vite sferica del centro di lavorazione Gantry ha, quindi, preso in considerazione un fattore importante, ovvero la sicurezza in qualsiasi ambiente di lavoro. Sono state messe in atto numerose funzioni di protezione che garantiscano la sicurezza dell'utente ogni volta che la macchina è in funzione. Alcune includono pulsanti di emergenza, guardie luminose, paratie di sicurezza e cambi utensili automatici, tra gli altri. I produttori hanno anche fornito addestramento sulla sicurezza per rendere gli utenti consapevoli dei possibili pericoli e su come evitarli.

Il bullone a vite sferica del centro di lavorazione Gantry è uno strumento multifunzionale utilizzato in molte industrie, tra cui quelle automobilistica, aerospaziale, medica e difesa, tra le tante altre. La versatilità di questo dispositivo migliora la capacità dell'utente di produrre diversi tipi di prodotti da materie prime varie. Sarà quindi molto utile per il foratura, fresatura e taglio di vari materiali nel corso di diverse attività di produzione.

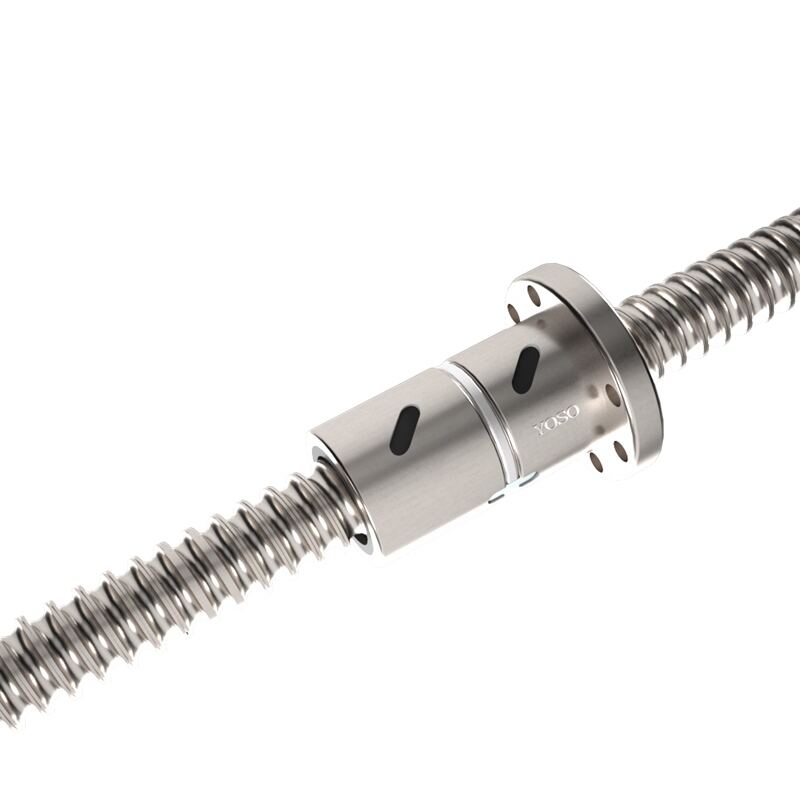

YOSO è specializzato in tutti i tipi di trasmissioni meccaniche. Le linee più recenti di viti meccaniche per centri di lavorazione a gantry producono guide lineari rotolate singole fino a 6 metri in varie dimensioni. Le guide possono arrivare fino a 125 pollici di lunghezza. Le guide vengono prodotte in un'intera serie di 25, 30, 35, 45, 55, 65, 85, 100, 125. Un singolo carrello può supportare un peso massimo di 192 tonnellate. Le basi di produzione delle viti sono in grado di produrre lotte con diametro minimo Ph6mm e passo medio di 1mm fino a un diametro massimo Ph245mm; la lunghezza della vite è di 10m con una capacità dinamica massima di 125 tonnellate. Offre set di viti meccaniche C1 livello 2 metri, C2 livello batch, 5 metri C3 livello, 10 metri C5 livello vari. YOSO Motion, il miglior compagno per sistemi lineari. Collaborerà e supporterà l'Industria 4.0. La tua percezione del Made in China è diversa.

Jingpeng Machinery fondata nel 2015 con sede a Shanghai e ha lanciato la filiale dell'UE in Polonia nel 2022, continuando a consolidare la propria presenza globale. Dopo 10 anni di sviluppo, YOSO è diventata una piattaforma integrata di commercio e industria nel campo della trasmissione meccanica. Ha il proprio marchio e brevetti internazionali. Jingpeng ha aderito allo stile aziendale che enfatizza "marchio nonché qualità del servizio" fin dall'inizio. YOSO è un marchio che ci permette di partecipare a mostre internazionali che mettono in mostra l'industria annualmente. La qualità è al cuore della crescita sostenibile di YOSO. Il servizio rende i nostri clienti partner commerciali. Jingpeng Machinery è diventata una piattaforma di acquisto leader per le trasmissioni meccaniche nell'ambito dell'industria 4.0. La fiducia si basa su 10 anni di produzione di prodotti senza difetti, 190 ingegneri che hanno praticato su 24 linee di produzione nonché su un'area di produzione di 50.000m2. Ogni trasmissione meccanica richiede decine di processi di produzione attentamente selezionati. YOSO si impegna a produrre prodotti perfetti.

Soluzione di integrazione della vite a billetto per centri di lavorazione YOSO fornisce componenti di controllo e trasmissione che possono essere acquistati in un unico punto, soddisfacendo le esigenze dei clienti. Siamo dedicati ad aiutare i clienti a essere più competitivi sul mercato, fornendo soluzioni di alta qualità per la produzione, l'efficienza e il potere di marketing del marchio con certificazione dei prodotti. La gamma di prodotti offre una vasta selezione di prestazioni superiori che ha guadagnato la fiducia sul mercato grazie alla nostra profonda comprensione dei requisiti dei clienti. Partner in tutto il mondo hanno stabilito relazioni più strette con YOSO, e la strategia di internazionalizzazione consente al marchio YOSO e ai concessionari di raggiungere i clienti in diverse regioni attraverso una rete globale. Se vorresti essere coinvolto come parte del marchio YOSO, contattami!

Marca: partecipazione a mostre internazionali per 10 anni. Il centro di fresatura a gantry ha al suo cuore sviluppo sostenibile delle viti senza fine. Servizio: i clienti sono partner. Soluzioni di trasmissione. YOSO addestra professionisti nel campo dei componenti di trasmissione all'interno dell'azienda, che analizzano perfettamente i requisiti dei disegni dei clienti e forniscono modelli finiti in 3D per facilitare gli accordi di produzione. Scambio industriale. YOSO è un importante partner degli eventi industriali tenuti in tutto il mondo, partecipando a questi scambi tra praticanti, imprenditorialità orientata alle applicazioni forward-looking e aziende leader, terreno importante per la nostra crescita.

La vite a sfera del centro di lavorazione a gantry è facile da usare e non è necessario avere una vasta esperienza per utilizzarla. Con un manuale su come usare la macchina, sei accompagnato e di solito le istruzioni passo-passo sono presenti nel manuale fornito insieme all'apparecchio. Hai la libertà di partecipare a sessioni di formazione offerte dal produttore, che ti forniranno le competenze appropriate per operare la macchina.

Copyright © Jingpeng Machinery&Equipment (Shanghai) Co., Ltd. Tutti i diritti riservati