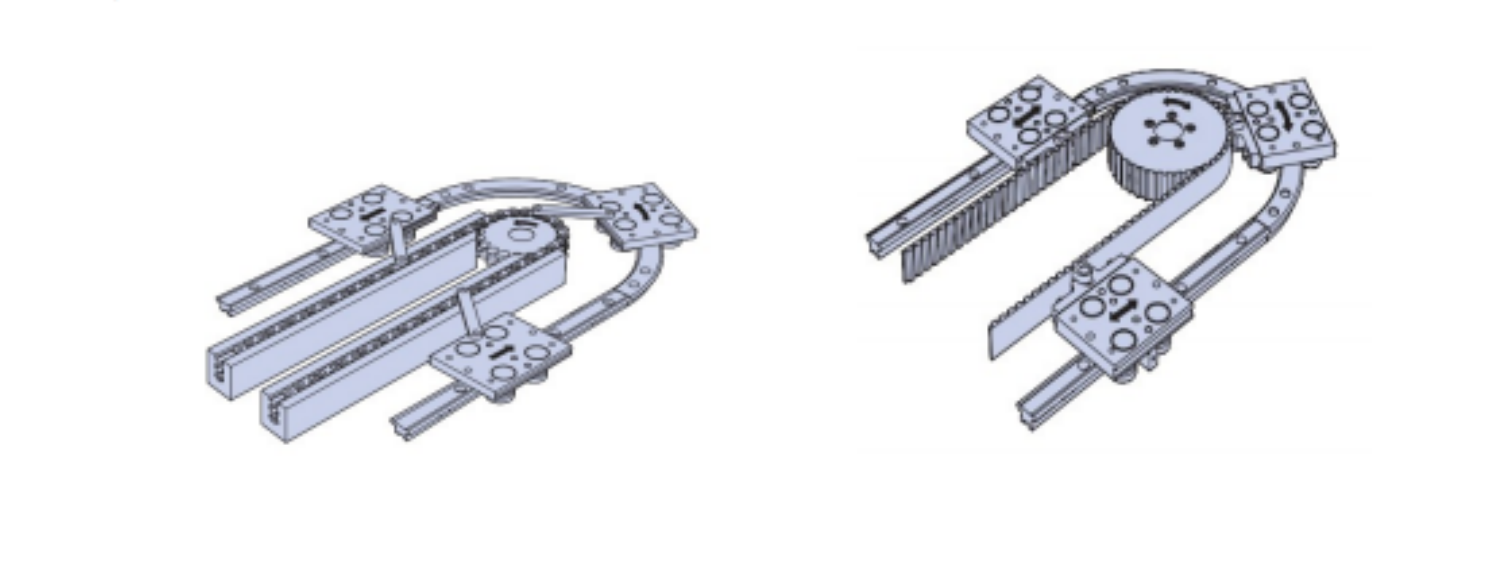

The installation method is more flexible. The gear-driven slide moves in an arc on the arc guide rail.

YOSO Circular Guide Rail Series

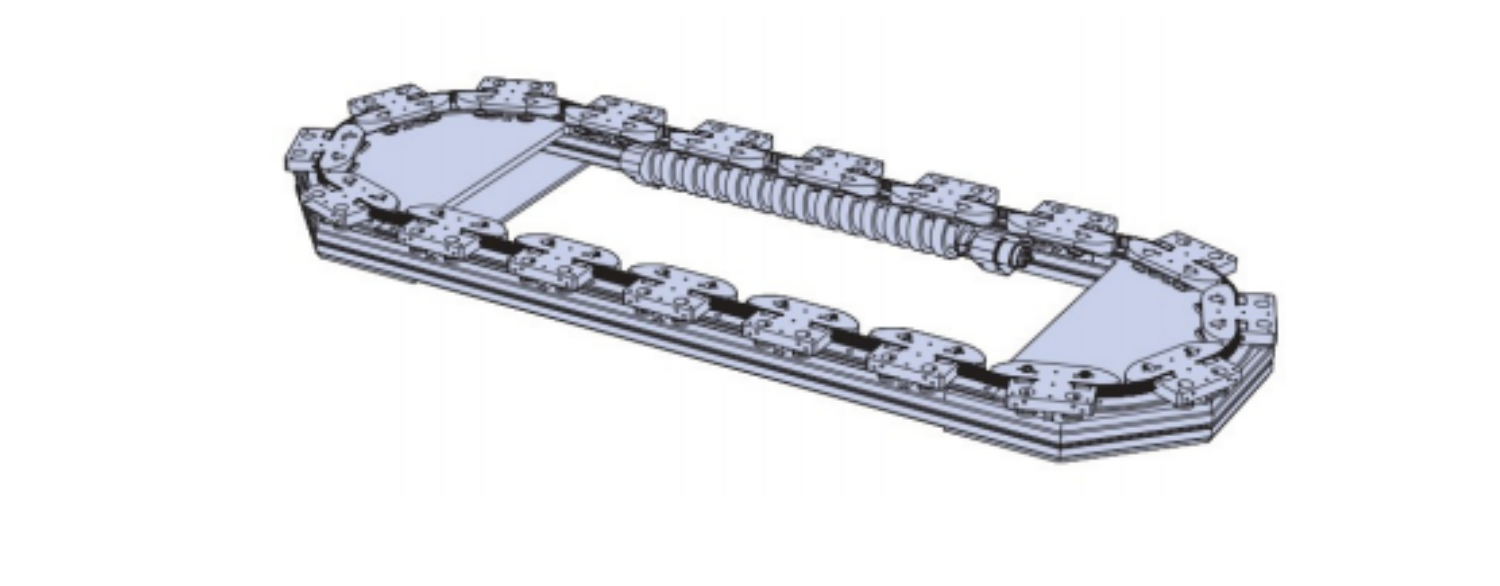

Arc linear guide have roller type linear guide rails and ball type linear guide rails,Can form precision ring guide rail; Coupled with the driving system,it can form a precision ring assembly line, ring production line or ring assembly line and other cycle lines. This kind of guideway circulation line,more compact structure, higher positioning accuracy, more configuration options; In many ways,it outperforms traditional delivery lines.

Modern production factories, always constantly looking for ways to reduce production costs, an automation direction is: put each station as close as possible together, reduce the workpiece in the distance between the station, and minimize the footprint of space;To achieve this,you need the workpiece to do ring motion, you need to use ring line.There are two types of ring wires, traditional non-guide and precision guide, which are described as follows:

Traditional belt type

Belt conveyor line, is a relatively simple structure, wide conveyor belt around the two rollers separated by a certain distance, the roller rotation,conveyor belt movement,drive the workpiece on the belt move. Roller conveyor line and belt conveyor line, the principle is similar, except that the belt is replaced by a number of densely arranged drums.

Non-guideway ring line, the workpiece is fixed on the belt or roller, is not rigid, is generated by the friction force of gravity, and can not well limit the workpiece left and right, front and back and up movement. In order to prevent the workpiece from falling out,it is necessary to add a baffle on both sides of the belt or drum. Because the workpiece is not fixed to the belt or roller, the workpiece often vibrates; If the shape of the workpiece is more complex, it will often be stuck together with the parts of the conveyor line.By the friction generated by gravity to fix the workpiece on the conveyor line, it can not ensure good positioning accuracy, more can not put the conveyor line up vertical. The fixed

workpiece is not rigid, which limits the moving speed of the conveyor line.

The workpiece is fixed on the slide seat, the slide seat rolls on the guide rail throughthe roller, the guide rail very well limits the freedom of the slide seat, only one direction offreedom of movement. Therefore, guideway type ring pipeline, with higher speed, higherpositioning accuracy, These two characteristics meet the requirement of precisionautomation.

To sum up, when you need to be in a small space, to achieve precision automation:workpiece quickly move between stations; After the motion stops, the workpiece has agood position accuracy; After the motion stops, additional force can be applied to theworkpiece for processing or assembly; Then you can choose a precise ring guide as thebasis for the design of your ring pipeline.

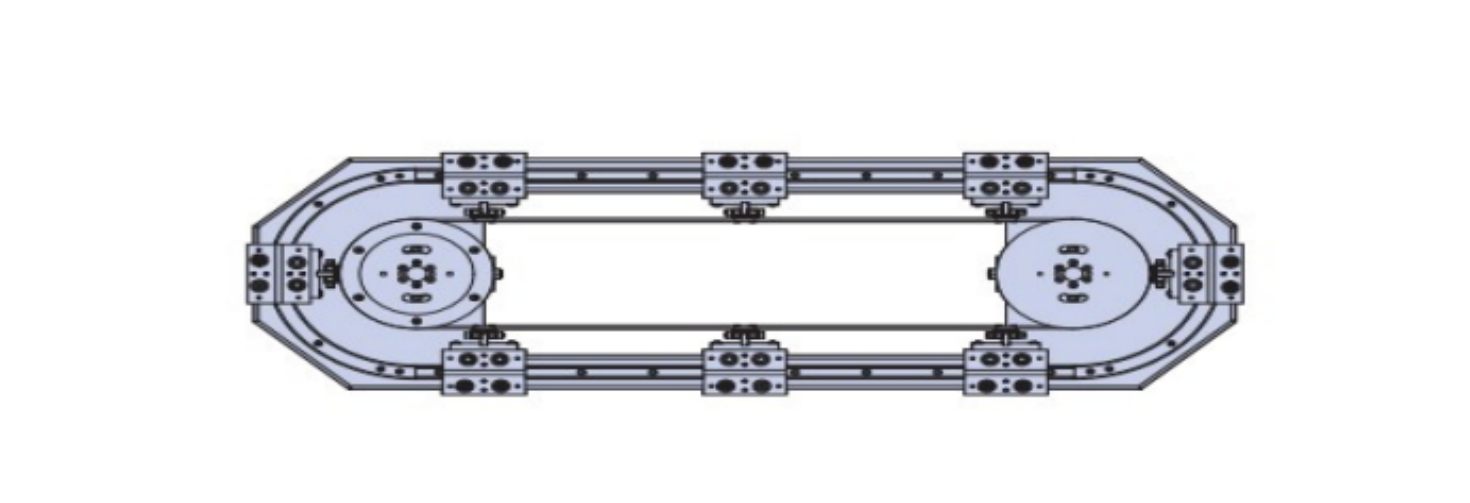

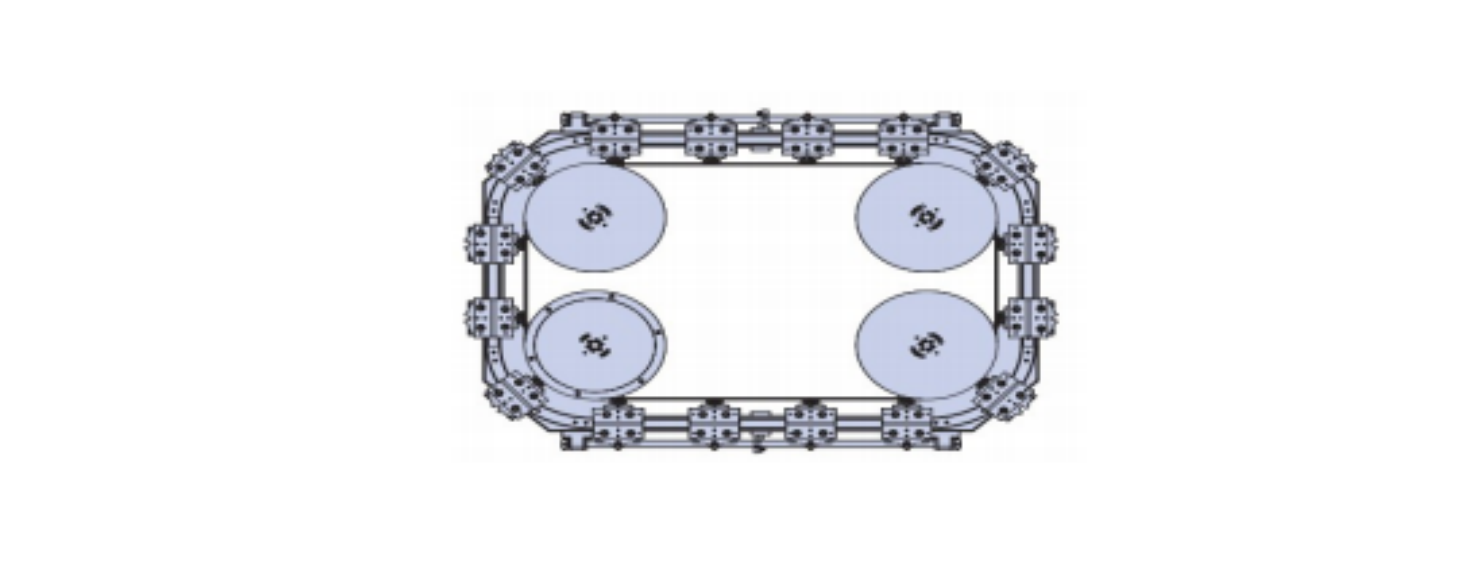

There are two main wavs to use annular guide rail for annular line: runway shape andsquare:

Arc linear guide, coupled with the drive system, becomes an annular assembly line.At present, there are three main driving modes: chain type, synchronous belt type ands crew type :

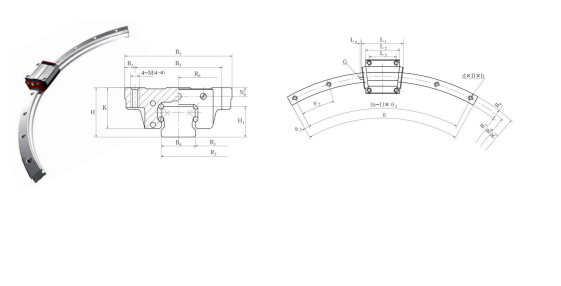

| Model | Guide rail size | Slider size | Oil cup size | ||||||||||

| H | B1 | B2 | B3 | K | L1 | L2 | L3 | M | Ф | L4 | G | N | |

| YCR16/168AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR16/228AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR16/300AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR16/390AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR25/230AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/400AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | MB | 7 | 11 | M6 | 6 |

| YCR25/500AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/750AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/1000AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR35/600AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/800AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/1000AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/1300AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| Guide rall sire | Minimum end angle | Rated dymamic load | Rated static load | Rated static moment | Slide wright kg | Rall weight Kg/m | Model | |||||||||

| B4 | H1 | daDuh | Θ | RΘ | R1 | R2 | Θm | Θ1 | C (MN) | (KN) | MA (N-m) | Mb (N·m) | Mc (N-m) | |||

| 16 | 15 | 4.5x7.5x5.3 | 15° | 168 | 160 | 176 | 160° | 3° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | YCR16/16BAA(AB) |

| 16 | 15 | 45x7.5x5.3 | 15° | 228 | 220 | 236 | 160° | 3° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 15 | YCR:16/228AA(AB) |

| 16 | 15 | 45x7.5x5.3 | 15° | 300 | 292 | 30g | 75° | 2° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | VCR16/30GAA(AB) |

| 16 | 15 | 4.5x7.5x5.3 | 15 | 390 | 382 | 398 | 65° | 2° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | YCR 16/39GAA(AB) |

| 23 | 22 | 7x11x9 | 15° | 230 | 218.5 | 241.5 | 160° | 3° | 16.8 | 21.5 | 142.2 | 142.2 | 233.5 | 0.59 | 3.3 | YCR25/23GAA(AB) |

| 23 | 22 | 7x11x9 | 10° | 400 | 388.5 | 411.5 | 60° | 2° | 16.8 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 3.3 | YCR25/40GAA(AB) |

| 23 | 22 | 7x11x | 7° | 500 | 488.5 | 511.5 | 60° | 2° | 168 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 3.3 | YCR25/SOGAA(AB) |

| 23 | 22 | 7x11x9 | 5* | 750 | 738.5 | 751.5 | 35° | 2° | 16.8 | 21.5 | 142.2 | 142.2 | 233.5 | 0.99 | 3.3 | YCR25/75GAA(AB) |

| 23 | 22 | 7x11x | 4° | 10:00 | 988.5 | 1011.5 | 28° | 2° | 16.8 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 33 | YCR25/1000A.A(AB) |

| 34 | 29 | 9x14x12 | 9" | 600 | 583 | 617 | 60° | 2° | 3497 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | YCR 3S/SOGAA(AB) |

| 34 | 29 | 9x14x12 | 5.5 | 800 | 783 | 817 | 35° | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | VCR 35/BOGAA(AB) |

| 34 | 29 | 9x14x12 | 5° | 1000 | 983 | 1017 | 28* | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 65 | YCR3S/1000AA(AB) |

| 34 | 29 | 9x14x12 | 3.5 | 1300 | 1283 | 1317 | 22° | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | YCR35/1300AA(AB) |

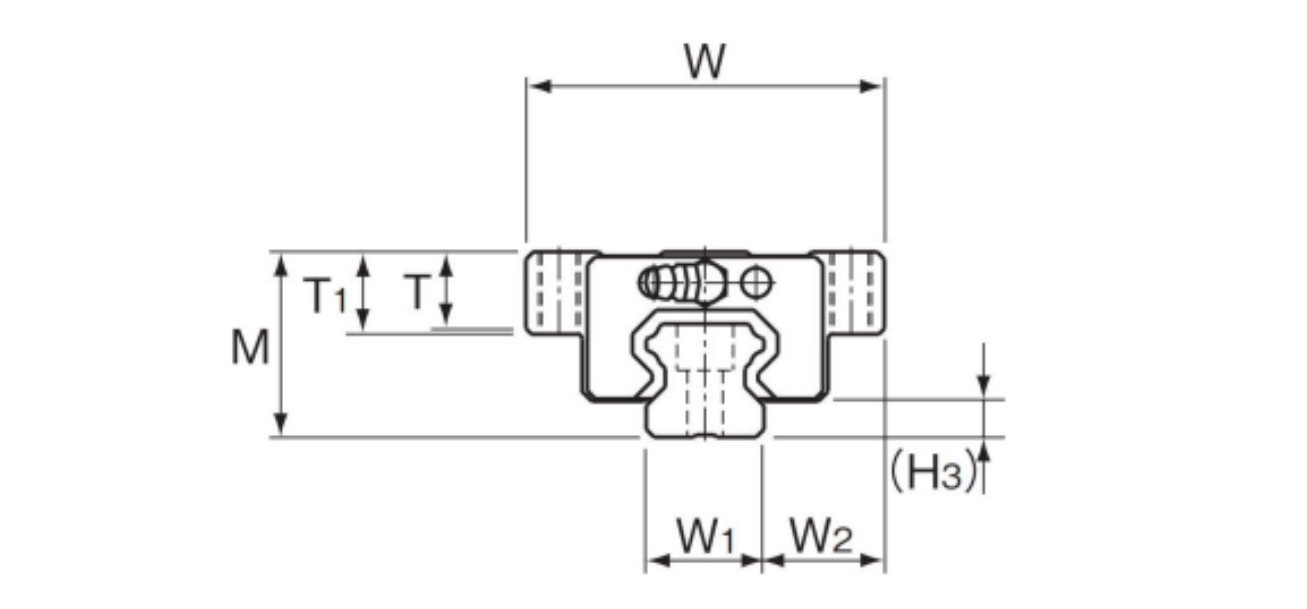

| Model No. | Outer dimensions | LM block dimensions | H3 | ||||||||||

| Height M | Width W | Length L | B | C | S | L1 | T | T1 | N | E | Grease Nipple | ||

| YCR15A+60/150R | 24 | 47 | 54.5 | 38 | 24 | M5 | 38.8 | 10.3 | 11 | 45 | 5.5 | PB1021B | 4.8 |

| YCR15A+60/300R | 55.5 | 28 | |||||||||||

| YCR15A+60/400R | 55.8 | 28 | |||||||||||

| YCR25A+60/500R | 36 | 70 | 81.6 | 57 | 45 | MB | 59.5 | 149 | 16 | 6 | 12 | B-M6F | 7 |

| YCR25A+60/750R | 82.3 | ||||||||||||

| YCR25A+60/1000R | 82.5 | ||||||||||||

| YCR35A+60/600R | 48 | 100 | 107.2 | 82 | 58 | M10 | 80.4 | 19.9 | 21 | 8 | 12 | B-M6F | 8.5 |

| YCR35A+60/800R | 107.5 | ||||||||||||

| YCR35A+60/1000R | 108.2 | ||||||||||||

| YCR35A+60/1300R | 108.5 | ||||||||||||

| YCR45A+60/800R | 60 | 120 | 136.7 | 100 | 70 | M12 | 98 | 239 | 25 | 10 | 16 | B-PT1/8 | 11.5 |

| YCR45A+60/1000R | 137.3 | ||||||||||||

| YCR45A+60/1200R | 137.3 | ||||||||||||

| YCR45A+60/1600R | 138 | ||||||||||||

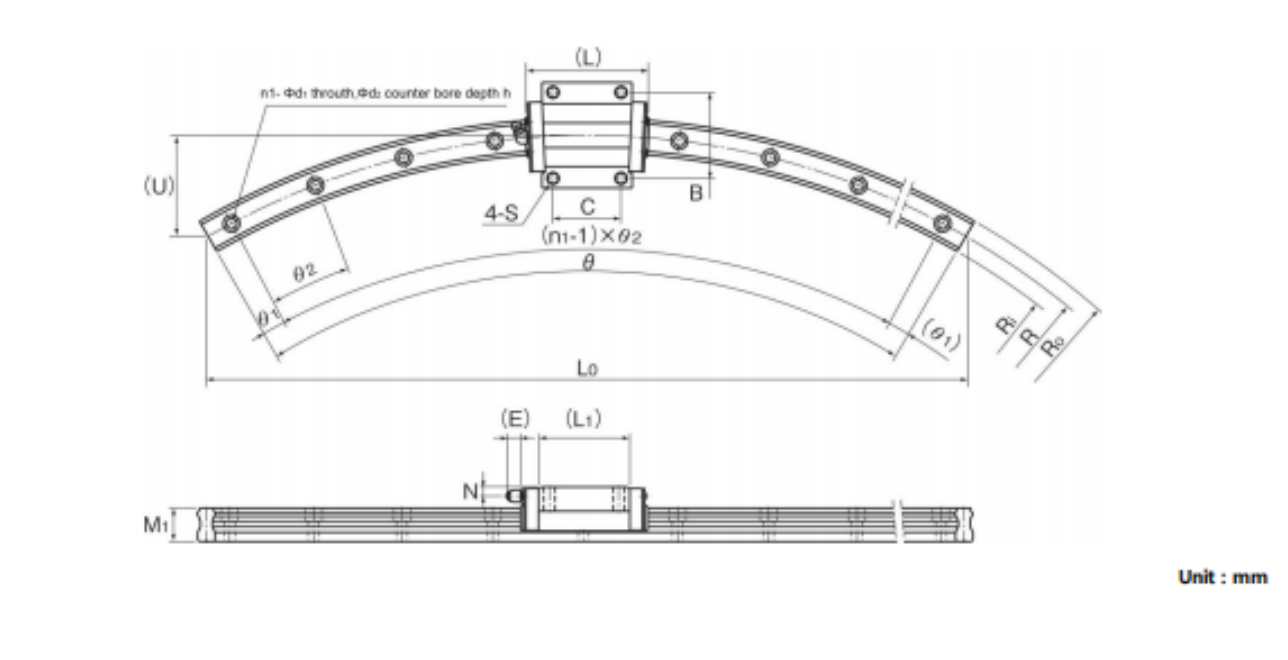

| LM rail dimensions | Basic load rating | Static permissible moment kN·m | Mass | ||||||||||||||||||

| R | RO | Ri | LO | U | Width W1 | W2 | Height M1 | d1xd2xh | m1 | Θ° | Θ° | Θ2 | kN | CO kN | MA | MB 0 | MC 6 | LM Block kg | LM Ral kg/m | ||

| 1 Block | Double Blocks | 1 Block | Double Blocks | 1 Block | |||||||||||||||||

| 150 | 157.5 | 142.5 | 150 | 20.1 | 15 | 16 | 15 | 4.5x7.5x5.3 | 3 | 7 | 23 | 6.66 | 10.8 | 0.0805 | 0.457 | 0.080 5 | 0.457 | 0.084 4 | 0.2 | 1.5 | |

| 300 | 307.5 | 2925 | 300 | 40 | 5 | 6 | 12 | 8.33 | 13.5 | ||||||||||||

| 400 | 407.5 | 392.5 | 400 | 54 | 7 | 3 | 9 | 8.33 | 13.5 | ||||||||||||

| 500 | 511.5 | 488.5 | 500 | 67 | 23 | 23.5 | 22 | 7x11x9 | 9 | 2 | 7 | 19.9 | 344 | 0.307 | 1.71 0 | .307 | 1.71 | 0.344 | 0.59 | 3.3 | |

| 750 | 761.5 | 738.5 | 750 | 100 | 12 | 2.5 | 5 | ||||||||||||||

| 1000 | 1011.5 | 988.5 | 1000 | 134 | 15 | 2 | 4 | ||||||||||||||

| 600 | 617 | 583 | 600 | 80 | 34 | 33 | 29 | 9x14x12 | 7 | 3 | 9 | 37.3 | 61.1 | 0.782 | 3.93 0 | .782 | 3.93 | 0.905 | 1.6 | 6.6 | |

| 800 | 817 | 793 | 800 | 107 | 11 | 2.5 | 5.5 | ||||||||||||||

| 1000 | 1017 | 983 | 1000 | 134 | 12 | 2.5 | 5 | ||||||||||||||

| 1300 | 1317 | 1283 | 1300 | 174 | 17 | 2 | 3.5 | ||||||||||||||

| 800 | 822.5 | 777.5 | 800 | 107 | 45 | 37.5 | 38 | 14x20x17 | 8 | 60 | 2 | 8 | 60 | 95.6 | 1.42 | 7.92 | 1.42 | 7.92 | 1.83 | 2.8 | 11.0 |

| 1000 | 1022.5 | 977.5 | 1000 | 134 | 10 | 3 | 6 | ||||||||||||||

| 12.00 | 1222.5 | 1177.5 | 1200 | 161 | 12 | 2.5 | 5 | ||||||||||||||

| 1600 | 1622.5 | 1577.5 | 1600 | 214 | 15 | 2 | 4 | ||||||||||||||

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved | Privacy policy