La guía recta-curva HMG es una nueva guía recta-curva que permite que el mismo tipo de bloques LM se mueva continuamente sobre rieles rectos y curvos combinando las tecnologías de LMGuide HSR y R Guide HCR. logra una drástica reducción de costos mediante la mejora de la eficiencia del trabajo en las líneas de montaje y transporte y los equipos de inspección y la simplificación de la estructura al eliminar un elevador y una mesa.

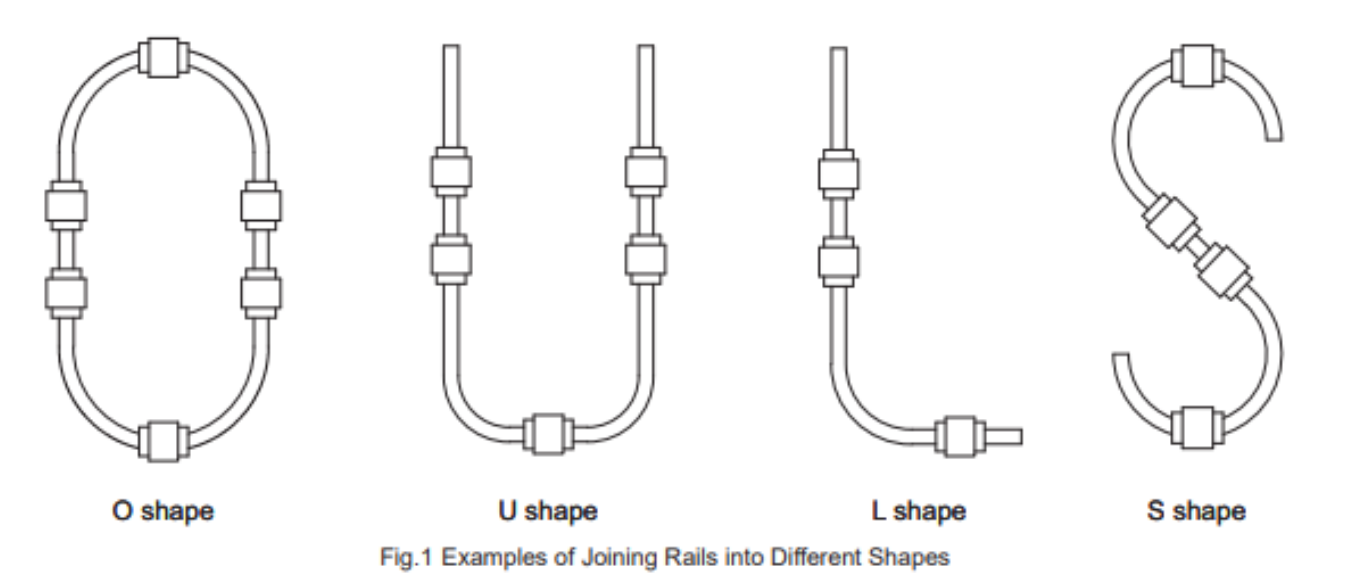

Libertad de diseño

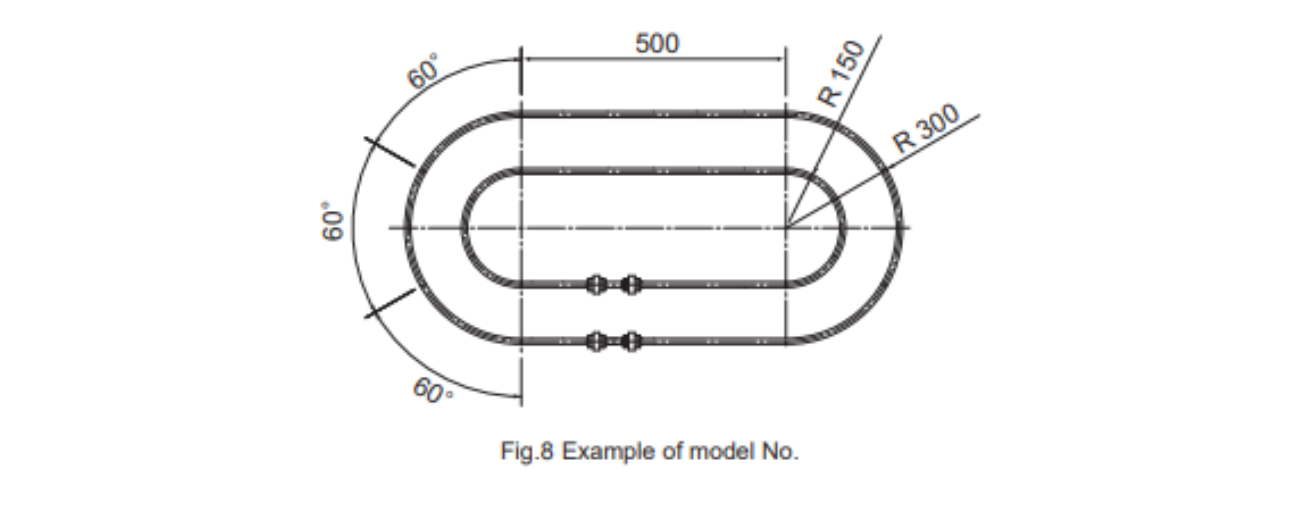

Permite combinaciones libres de formas rectas y curvas. Dado que los bloques LM pueden transitar suavemente entre las secciones rectas y curvas, se pueden unir varias combinaciones de rieles rectos y curvos en varias formas, como O, U, L y S. Además, HMG permite montar una mesa grande y transportar un objeto pesado mediante combinaciones de múltiples bloques en un solo riel o 2 o más rieles LM. Por tanto, proporciona una gran libertad de diseño.

Sellos rectos y curvos

El modelo HMG está disponible con sellos que se pueden usar tanto para secciones rectas como curvas para evitar la entrada de materiales extraños. Estos sellos rectos y curvos proporcionan sellado tanto para las secciones rectas como para las curvas, evitando que entren materiales extraños a la unidad.

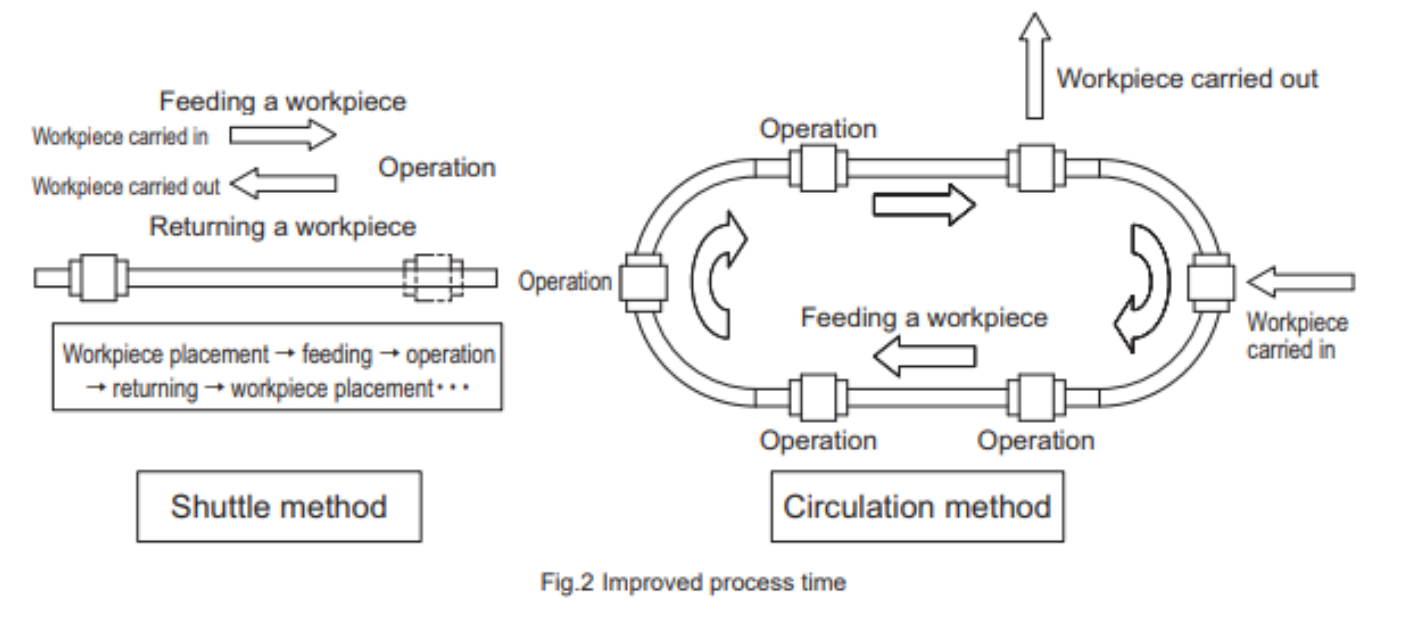

Tiempo de transporte reducido

A diferencia del método de lanzadera, el uso de unidades HMG en un sistema de circulación permite colocar piezas de trabajo mientras se inspeccionan o montan otras piezas de trabajo, lo que mejora significativamente el tiempo de proceso. Aumentar el número de mesas puede acortar aún más el tiempo de proceso.

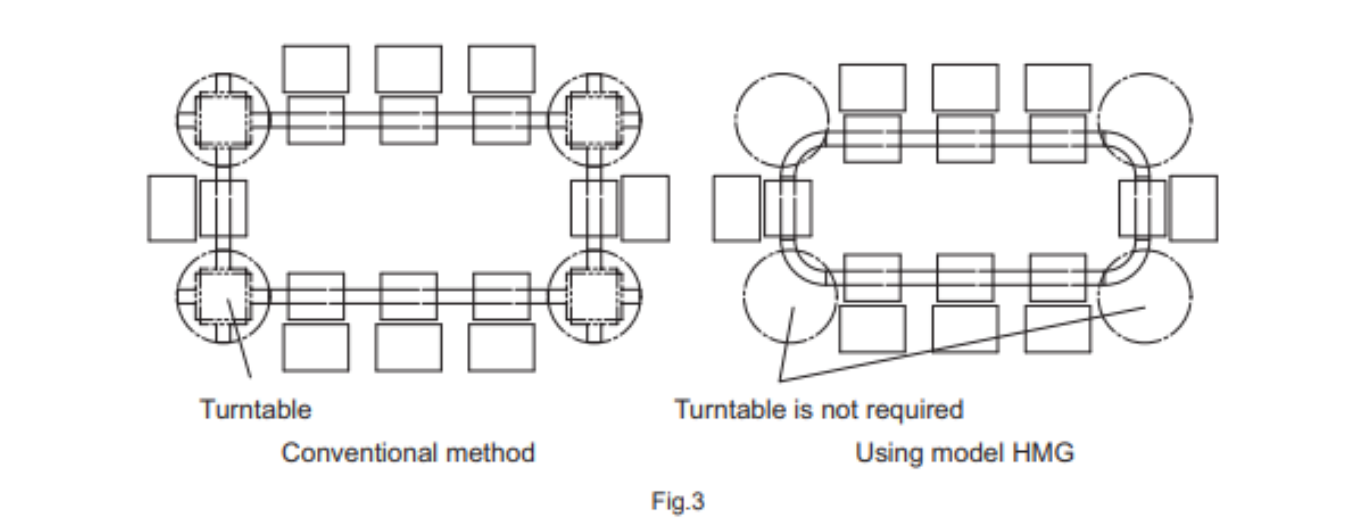

Reducción de costos mediante un mecanismo simplificado

La combinación de rieles rectos y curvos elimina un elevador y una plataforma giratoria utilizados convencionalmente para cambiar de dirección en las líneas de transporte y producción. Por lo tanto, el uso de HMG simplifica el mecanismo y elimina una gran cantidad de piezas, lo que permite reducir el coste. Además, también se pueden reducir las horas de trabajo en diseño.

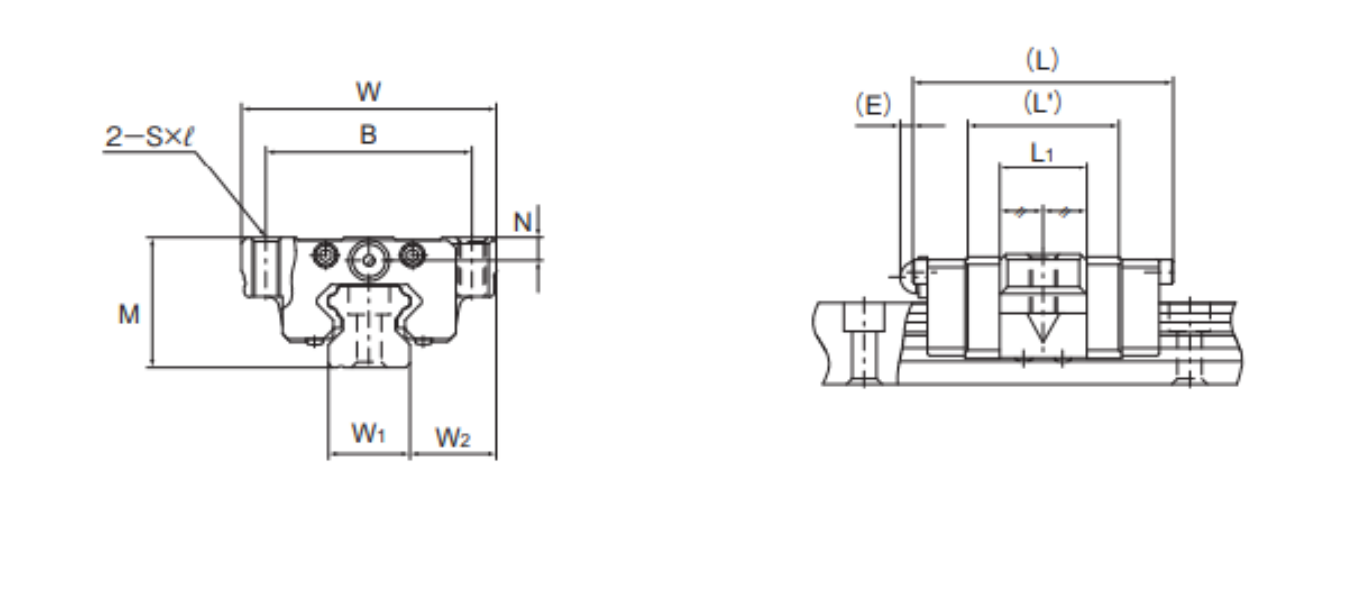

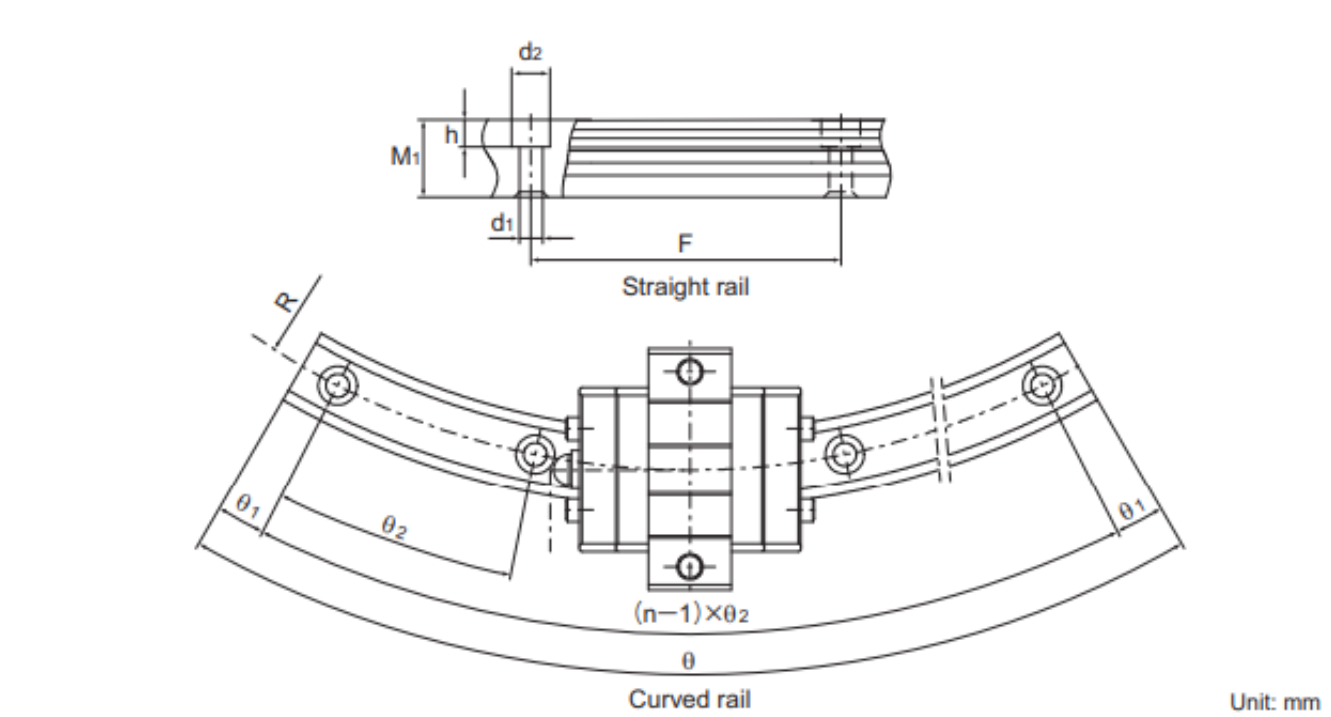

| N º de Modelo. | Dimensiones externas | Dimensiones del bloque LM | Dimensiones del carril LM | iones | |||||||||

| M | W | L | L' | B | Sxl | L1 | N | E | Carril recto | Altura M1 | |||

| W: | W2 | F | |||||||||||

| HMG-15A | 24 | 47 | 48 | 28.8 | 38 | M5x11 | 16 | 4.3 | 5.5 | 15 | 16 | 60 | 15 |

| HMG-25A | 36 | 70 | 62.2 | 42.2 | 57 | M8x16 | 25.6 | 6 | 12 | 23 | 23.5 | 60 | 22 |

| HMG-35A | 48 | 100 | 80.6 | 54.6 | 82 | M10x21 | 32.6 | 8 | 12 | 34 | 33 | 80 | 29 |

| HMG-45A | 60 | 120 | 107.6 | 76.6 | 100 | M12x25 | 42.6 | 10 | 16 | 45 | 37.5 | 105 | 38 |

| HMG-65A | 90 | 170 | 144.4 | 107.4 | 142 | M16x37 | 63.4 | 19 | 16 | 63 | 53.5 | 150 | 53 |

| Clasificación de carga dinámica básica (C) | Clasificación de carga estática básica (Co) | |||||||

| Orificio de montaje d1xd2xh | Carril curvo | |||||||

| R | n | 0° | 01° | 0. ° | Carga resultante (C)kN | Sección recta (C-st) kN | Sección curva (Car) kN | |

| 4.5x7.5x5.3 | 150 | 3 | 60 | 7 | 23 | 2.56 | 4.23 | 0.44 |

| 300 | 5 | 60 | 6 | 12 | ||||

| 400 | 7 | 60 | 3 | 9 | ||||

| 7x11x9 | 500 | 9 | 60 | 2 | 7 | 9.41 | 10.8 | 6.7 |

| 750 | 12 | 60 | 2.5 | 5 | ||||

| 1000 | 15 | 60 | 2 | 4 | ||||

| 9x14x12 | 600 | 7 | 60 | 3 | 9 | 17.7 | 19 | 11.5 |

| 800 | 11 | 60 | 2.5 | 5.5 | ||||

| 1000 | 12 | 60 | 2.5 | 5 | ||||

| 1300 | 17 | 60 | 2 | 3.5 | ||||

| 14x20x17 | 800 | 8 | 60 | 2 | 8 | 28.1 | 29.7 | 18.2 |

| 1000 | 10 | 60 | 3 | 6 | ||||

| 1200 | 12 | 60 | 2.5 | 5 | ||||

| 1600 | 15 | 60 | 2 | 4 | ||||

| 18x26x22 | 1000 | 8 | 60 | 2 | 8 | 66.2 | 66.7 | 36.2 |

| 1500 | 10 | 60 | 3 | 6 | ||||

| 2000 | 12 | 45 | 0.5 | 4 | ||||

| 2500 | 13 | 45 | 1.5 | 3.5 | ||||

| 3000 | 10 | 30 | 1.5 | 3 | ||||

| N º de Modelo. | Dimensión del carril articulado. | |||||||

| Altura | Paso | Agujero de montaje | Ancho | Longitud del cono | Profundidad cónica | Radio de busqueda | ||

| M: | F | dixd.xh | W1 | W. | a | b | R | |

| 15A | 15 | 60 | 4.5x7.5x5.3 | 15 | 14.78 | 28 | 0.22 | 150 |

| 14.89 | 0.11 | 300 | ||||||

| 14.92 | 0.08 | 400 | ||||||

| 25A | 22 | 60 | 7x11x9 | 23 | 22.83 | 42 | 0.17 | 500 |

| 22.89 | 0.11 | 750 | ||||||

| 22.92 | 0.08 | 1000 | ||||||

| 35A | 29 | 80 | 9x14x12 | 34 | 33.77 | 54 | 0.23 | 600 |

| 33.83 | 0.17 | 800 | ||||||

| 33.86 | 0.14 | 1000 | ||||||

| 33.9 | 0.1 | 1300 | ||||||

| 45A | 38 | 105 | 14x20x17 | 45 | 44.71 | 76 | 0.29 | 800 |

| 44.77 | 0.23 | 1000 | ||||||

| 44.81 | 0.19 | 1200 | ||||||

| 44.86 | 0.14 | 1600 | ||||||

| 65A | 53 | 150 | 18x26x22 | 63 | 62.48 | 107 | 0.52 | 1000 |

| 62.66 | 0.34 | 1500 | ||||||

| 62.74 | 0.26 | 2000 | ||||||

| 62.8 | 0.2 | 2500 | ||||||

| 62.83 | 0.17 | 3000 | ||||||

Derechos de autor © Jingpeng Machinery&Equipment(Shanghai) Co., Ltd. Todos los derechos reservados