The Straight Curved Guide YS-HMG is a new straight curved guide that combines the technologies of the LM Guide YGH and R Guide YCR to enable the same type of LM slider to move continuously on straight and curved tracks. lt has achieved significant cost reduction by improving the work efficiency of assembly and conveyor lines and inspection equipment, and simplifying the structure by eliminating lifts and workbenches.

It allows free combinations of straight and curved shapes.

Since LM blocks can smoothly transit between the straight and curved sections, various combinations of straight and curved rails can be joined into various shapes such as O, U, L and S shapes. In addition, YS-HMG allows a large table to be mounted and a heavy object to be carried through combinations of multiple blocks on a single rail or 2 or more LM rails. Thus, it provides great freedom of design.

The Model YS-HMG is available with seals that can be used for both straight and curved sections to prevent foreign materials from entering. These straight-curved seals provide sealing for both the straight and curved sections, preventing foreign materials from entering the unit.

Unlike the shuttle method, using YS-HMG units in a circulating system allows workpieces to be placed while other workpieces are being inspected or mounted, thus to significantly improve process time. Increasing the number of tables can further shorten process time.

Combination of straight and curved rails eliminates a lift and a turntable conventionally used for changing directions in the conveyance and production lines. Therefore, use of YS-HMG simplifies the mechanism and eliminates a large number of parts, allowing the cost to be reduced. Additionally, man-hours in designing can also be reduced.

The Straight-Curved Guide YS-HMG requires a rotating mechanism or a slide mechanism for the table to rotate the curved sections when 2 or more rails are used or when 2 or more LM blocks are connected on a single rail. Refer to Fig.4 for examples of such mechanisms.

Fig.5 shows examples of designing a table when units are used on multiple axes. YS-HMG requires a rotating mechanism and a slide mechanism since the table is decentered when an LM block transits from a straight section to a curved section. The amount of decentering differs according to the radius of the curved section and the LM block span. Therefore, it is necessary to design the system in accordance with the corresponding specifications.

Fig.6 shows detail drawings of the slide and rotating mechanisms. In the figure, LM Guides are used in the slide mechanism and Cross-Roller Rings in the rotating mechanism to achieve smooth sliding and rotating motions.

For driving the Straight-Curved Guide, belt drives and chain drives are available.

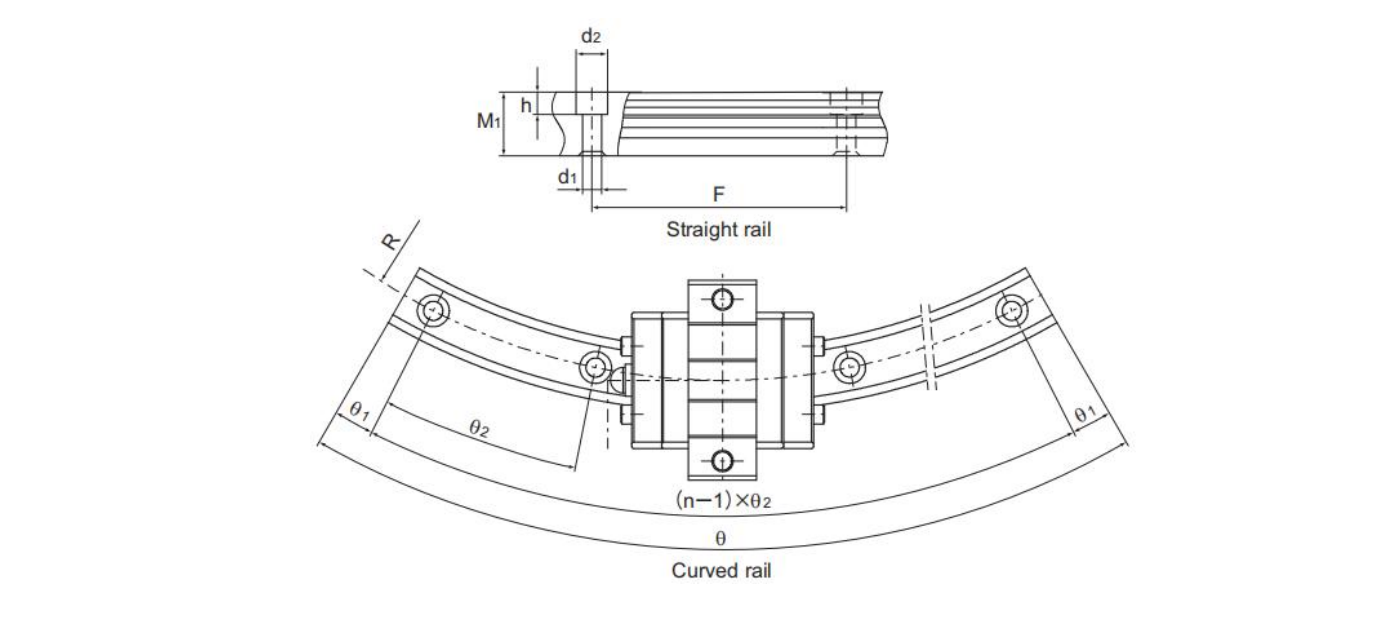

| Model No. | Outerdimensions | LM block dimensions | LM rail dimensions | ||||||||||

| M | W | L | L | B | Sxt | Li | N | E | Straight rail |

Height M₁ |

|||

| W₁ | W₂ | F | |||||||||||

| YS-HMG 15A | 24 | 47 | 48 | 28.8 | 38 | M5x11 | 16 | 4.3 | 5.5 | 15 | 16 | 60 | 15 |

| YS-HMG 25A | 36 | 70 | 62.2 | 42.2 | 57 | M8x16 | 25.6 | 6 | 12 | 23 | 23.5 | 60 | 22 |

| YS-HMG 35A | 48 | 100 | 80.6 | 54.6 | 82 | M10x21 | 32.6 | 8 | 12 | 34 | 33 | 80 | 29 |

| YS-HMG 45A | 60 | 120 | 107.6 | 76.6 | 100 | M12x25 | 42.6 | 10 | 16 | 45 | 375 | 105 | 38 |

| YS-HMG 65A | 90 | 170 | 144.4 | 107.4 | 142 | M16x37 | 63.4 | 19 | 16 | 63 | 53.5 | 150 | 53 |

| LM rail dimensions |

Basic dynamic load rating(C) |

Basic static load rating (Co) | |||||||||||

|

Mounting hole d xd₂ ×h |

Curved rai | ||||||||||||

| R | n | 0° | 0i | θ₂ ° |

Resultant load C)kN |

Straight section Cost)kN |

Curved section (Co r)kN |

||||||

| 4.5×75×5.3 | 150 | 3 | 60 | 7 | 23 | 2.56 | 4.23 | 044 | |||||

| 300 | 5 | 60 | 6 | 12 | |||||||||

| 400 | 7 | 60 | 3 | 9 | |||||||||

| 7×11×9 | 500 | 9 | 60 | 2 | 7 | 9.41 | 10.8 | 6.7 | |||||

| 750 | 12 | 60 | 2.5 | 5 | |||||||||

| 1000 | 15 | 60 | 2 | 4 | |||||||||

| 9×14×12 | 600 | 7 | 60 | 3 | 9 | 177 | 19 | 11.5 | |||||

| 800 | 11 | 60 | 2.5 | 5.5 | |||||||||

| 1000 | 12 | 60 | 2.5 | 5 | |||||||||

| 1300 | 17 | 60 | 2 | 3.5 | |||||||||

| 14×20×17 | 800 | 8 | 60 | 2 | 8 | 28.1 | 297 | 18.2 | |||||

| 1000 | 10 | 60 | 3 | 6 | |||||||||

| 1200 | 12 | 60 | 2.5 | 5 | |||||||||

| 1600 | 15 | 60 | 2 | 4 | |||||||||

| 18×26×22 | 1000 | 8 | 60 | 2 | 8 | 66.2 | 66.7 | 362 | |||||

| 1500 | 10 | 60 | 3 | 6 | |||||||||

| 2000 | 12 | 45 | 0.5 | 4 | |||||||||

| 2500 | 13 | 45 | 1.5 | 3.5 | |||||||||

| 3000 | 10 | 30 | 1.5 | 3 | |||||||||

| Table¹Static Permissible Moments of Model YS-HMG | |||||||||||||

| Model No. | MA |

M 口 口 |

|||||||||||

| Straight section | Curved section | Straight section | Curved section | Straight section | Curved section | ||||||||

| YS-HMG 15 | 0.008 | 0.007 | 0.008 | 0.01 | 0.027 | 0.003 | |||||||

| YS-HMG 25 | 01 | 004 | 01 | 0.05 | 011 | 0.07 | |||||||

| YS-HMG 35 | 0.22 | 0.11 | 022 | 012 | 0.29 | 0.17 | |||||||

| YS-HMG 45 | 0.48 | 0.2 | 0.48 | 022 | 0.58 | 0.34 | |||||||

| YS-HMG 65 | 1.47 | 0.66 | 1.47 | 073 | 1.83 | 0.94 | |||||||

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved