Innovation-driven, improving screw production technology

On July 20, 2024, after several months of technology research and development and equipment upgrades, Jingpeng Machinery successfully put into use a new high-precision ball screw production line. The launch of this new production line not only significantly improved production efficiency, but also greatly enhanced the company's competitiveness and product quality in the global market.

As an industry-leading screw manufacturer, we have always adhered to the strategy of parallel technological innovation and product upgrading. "Technological innovation is one of the core driving forces for our corporate development. The commissioning of the new production line is an important sign that we continue to improve product accuracy, stability and production efficiency, and can better meet the increasingly stringent market demands. We have always adhered to Focus on customers and provide high-performance screw solutions with higher added value. ”

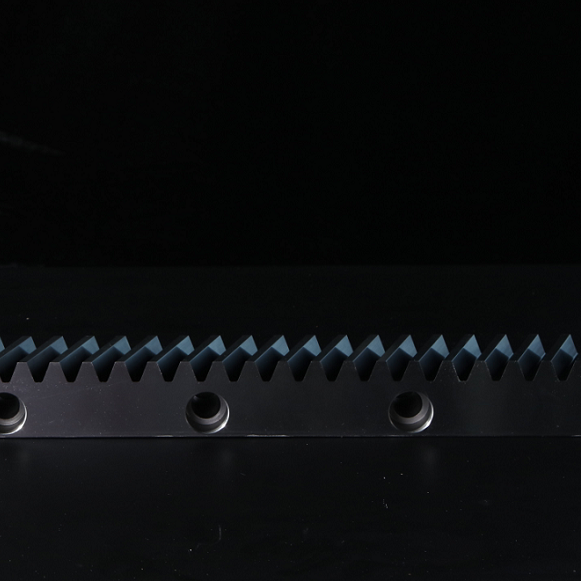

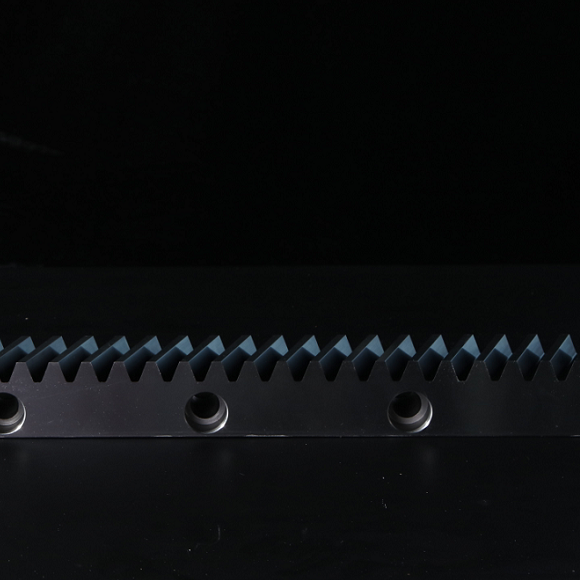

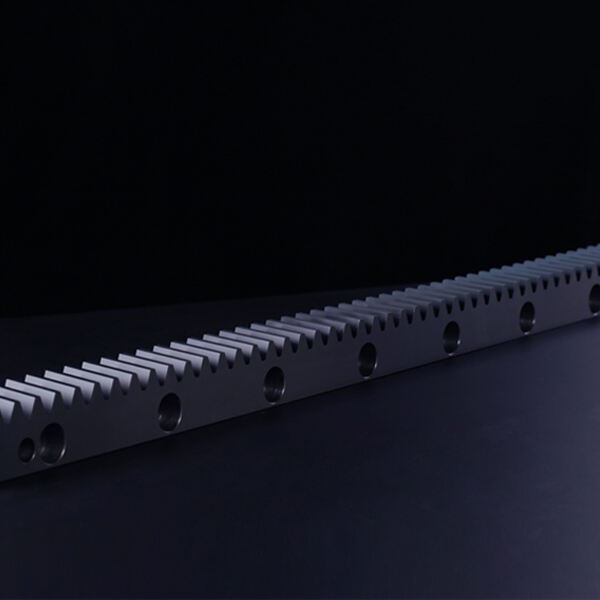

The upgraded new production line is equipped with the world's leading automation equipment and intelligent production system, which can more accurately control the production process of the product and ensure the high precision and durability of each screw rod. These high-precision ball screws are widely used in many fields such as precision machinery, CNC equipment, robots and automated production lines, and are especially suitable for applications requiring high load and high precision.

The new production line not only improves the accuracy and load capacity of our products, but also expands our market share in precision machinery, automation equipment and other industries. In order to ensure that product quality is always at the leading level in the industry, Jingpeng Machinery has also established an independent quality inspection center to conduct strict quality control on each batch of screw products to ensure that every product delivered to customers meets international standards.

Recommended Products

Hot News

-

Jingpeng Machinery | Presented at the world's five major industrial events with intelligent motion control solutions

2025-02-11

-

Jingpeng Machinery's new office is open, dedicated to providing customers with better services

2024-12-31

-

Customer first, we provide you with customized screw solutions

2024-12-30

-

Innovation-driven, improving screw production technology

2024-12-30

-

Japanese engineers with twenty years of experience in the industry came to Jingpeng to gain an in-depth understanding of the products and carry out cooperation

2024-02-18

-

The last stop for Polish customers is Jingpeng headquarters, cooperation starts with trust

2022-12-28

-

Russian customers visited Jingpeng headquarters in November, and the two parties successfully reached a strategic cooperation

2023-05-24

-

Japanese engineers visited Jingpeng headquarters to learn more about the products and successfully placed orders

2023-03-17

-

Tunisian customers praised Jingpeng Machinery’s large screw production capabilities and brought non-standard customized samples to discuss cooperation plans

2023-06-21

-

Turkish customers visited Jingpeng factory and successfully placed orders

2023-01-11

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ