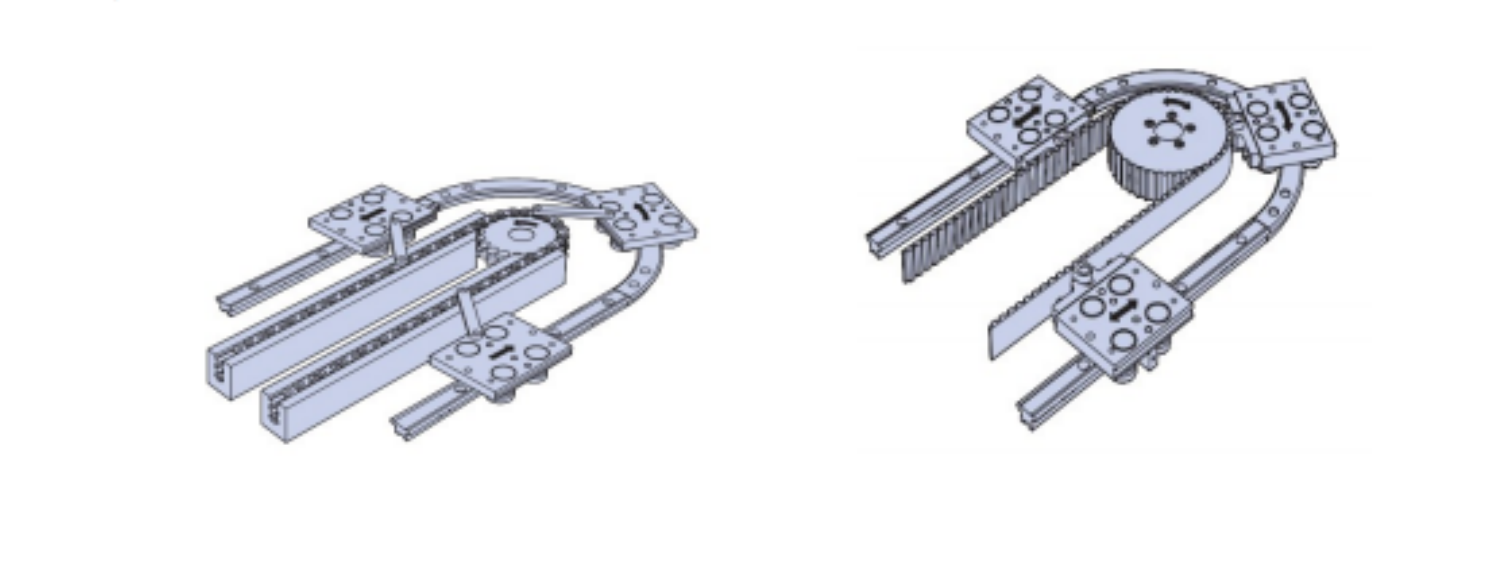

Njia ya ufungaji ni rahisi zaidi. Slaidi inayoendeshwa na gia husogea kwenye safu kwenye reli ya mwongozo wa arc.

Mfululizo wa Reli ya Mwongozo wa YOSO

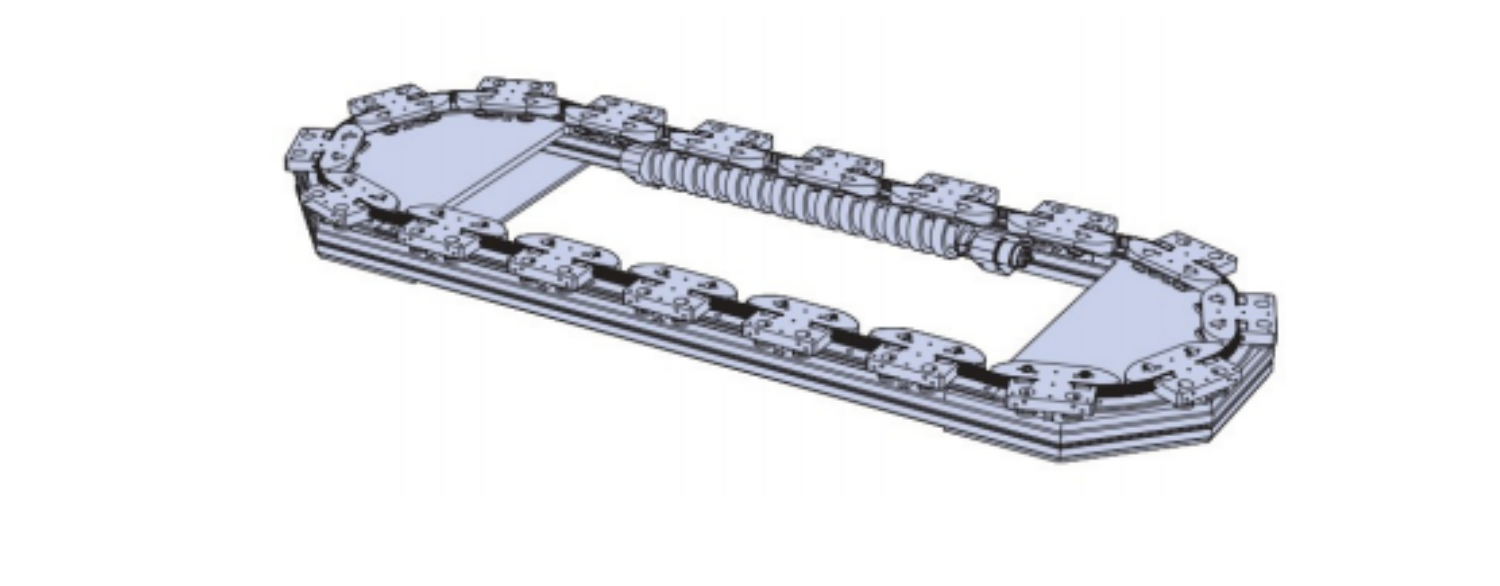

Mwongozo wa mstari wa safu ya arc una reli za mwongozo wa aina ya roller na reli za mwongozo wa aina ya mpira, Inaweza kuunda reli ya mwongozo wa pete kwa usahihi; Pamoja na mfumo wa kuendesha gari, inaweza kuunda mstari wa mkusanyiko wa pete sahihi, mstari wa uzalishaji wa pete au mstari wa mkutano wa pete na mistari mingine ya mzunguko. Aina hii ya mstari wa mzunguko wa mwongozo, muundo wa kompakt zaidi, usahihi wa nafasi ya juu, chaguzi zaidi za usanidi; Kwa njia nyingi, inapita njia za kawaida za utoaji.

Viwanda vya kisasa vya uzalishaji, kila mara hutafuta njia za kupunguza gharama za uzalishaji, mwelekeo wa otomatiki ni: weka kila kituo karibu iwezekanavyo pamoja, punguza sehemu ya kazi katika umbali kati ya kituo, na punguza alama ya nafasi; Ili kufanikisha hili, wewe haja ya workpiece kufanya pete mwendo, unahitaji kutumia pete line.Kuna aina mbili za waya pete, jadi yasiyo ya mwongozo na mwongozo wa usahihi, ambayo ni ilivyoelezwa kama ifuatavyo:

Aina ya ukanda wa jadi

Ukanda conveyor line, ni muundo rahisi, upana conveyor ukanda kuzunguka rollers mbili kutengwa kwa umbali fulani, mzunguko roller, harakati conveyor ukanda, kuendesha workpiece juu ya hoja ukanda. Roller conveyor line na ukanda conveyor line, kanuni ni sawa, isipokuwa kwamba ukanda ni kubadilishwa na idadi ya ngoma zenye mpangilio.

Mstari usio na mwongozo wa pete, workpiece ni fasta juu ya ukanda au roller, si rigid, ni yanayotokana na nguvu msuguano wa mvuto, na hawezi vizuri kikomo workpiece kushoto na kulia, mbele na nyuma na juu ya harakati. Ili kuzuia workpiece kutoka kuanguka nje, ni muhimu kuongeza baffle pande zote mbili za ukanda au ngoma. Kwa sababu workpiece haijawekwa kwa ukanda au roller, workpiece mara nyingi hutetemeka; Ikiwa sura ya workpiece ni ngumu zaidi, mara nyingi itaunganishwa pamoja na sehemu za mstari wa conveyor.Kwa msuguano unaozalishwa na mvuto wa kurekebisha workpiece kwenye mstari wa conveyor, haiwezi kuhakikisha usahihi mzuri wa nafasi, zaidi haiwezi. weka mstari wa conveyor juu wima. Iliyowekwa

workpiece sio rigid, ambayo hupunguza kasi ya kusonga ya mstari wa conveyor.

Sehemu ya kazi imewekwa kwenye kiti cha slaidi, kiti cha slaidi kinazunguka kwenye reli ya mwongozo kupitia roller, reli ya mwongozo inaweka mipaka ya uhuru wa kiti cha slaidi, mwelekeo mmoja tu wa uhuru wa harakati. Kwa hiyo, bomba la pete ya aina ya njia, na kasi ya juu, usahihi wa nafasi ya juu, Tabia hizi mbili zinakidhi mahitaji ya usahihi wa automatisering.

Kwa muhtasari, wakati unahitaji kuwa katika nafasi ndogo, ili kufikia usahihi wa automatisering:workpiece haraka hoja kati ya vituo; Baada ya kuacha mwendo, workpiece ina usahihi wa nafasi nzuri; Baada ya mwendo kusimama, nguvu ya ziada inaweza kutumika kwa workpiece kwa ajili ya usindikaji au kusanyiko; Kisha unaweza kuchagua mwongozo sahihi wa pete kama msingi wa muundo wa bomba lako la pete.

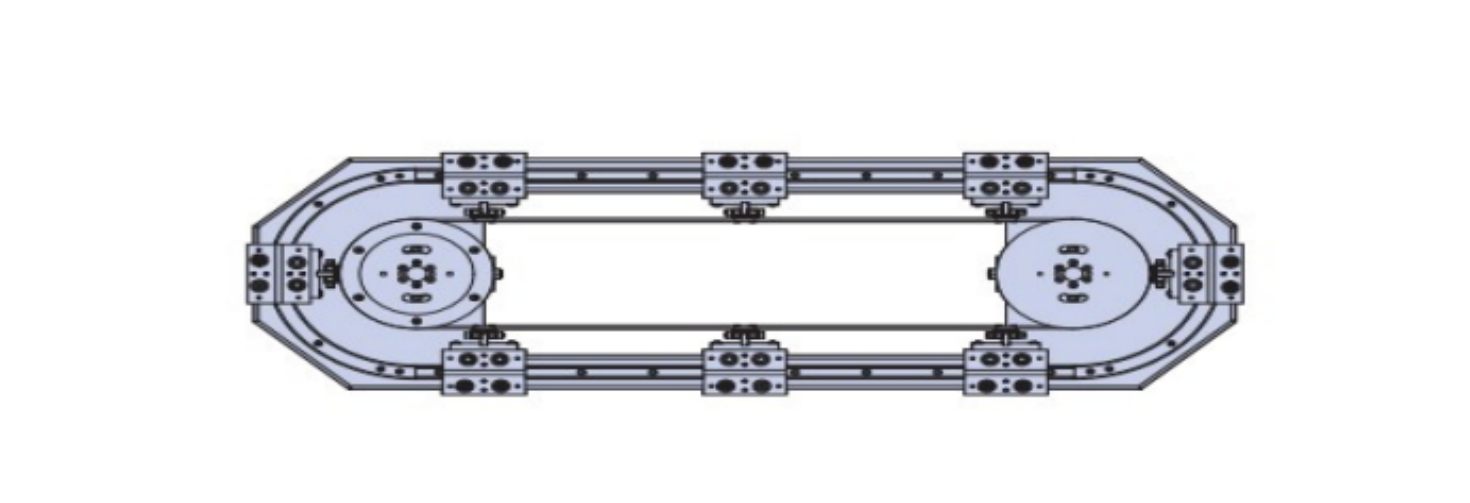

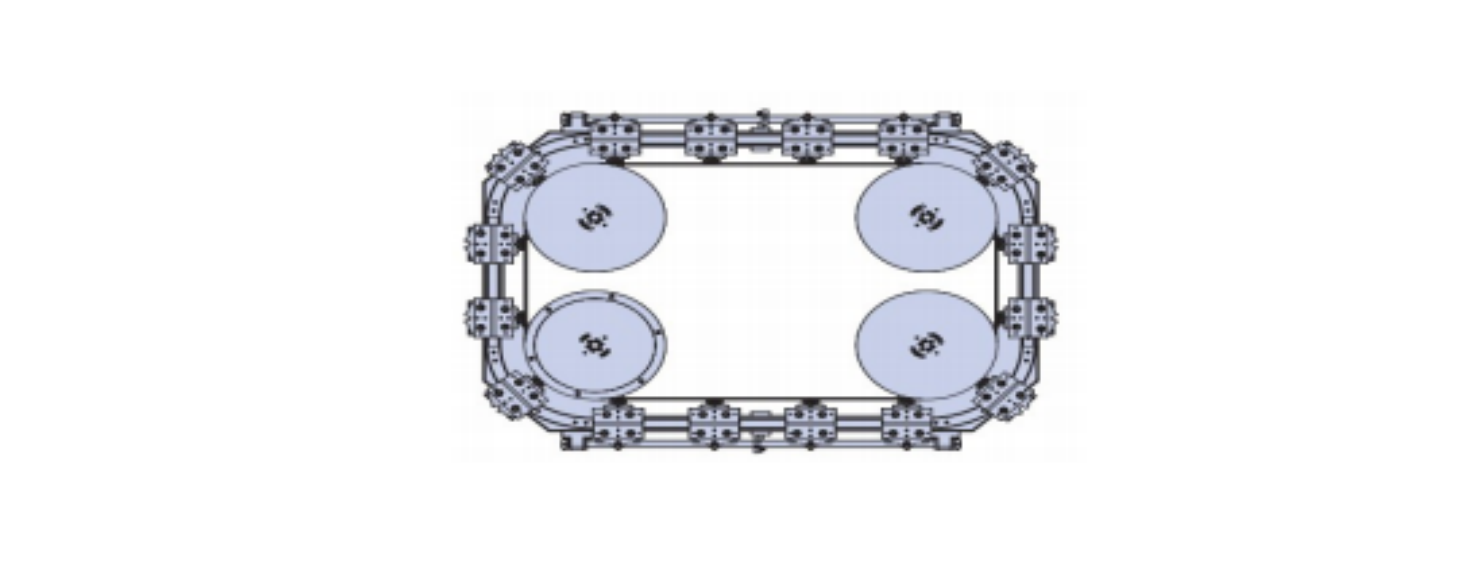

Kuna mawimbi mawili kuu ya kutumia reli ya mwongozo wa annular kwa mstari wa annular: sura ya njia ya kuruka na mraba:

Mwongozo wa mstari wa Arc, pamoja na mfumo wa kiendeshi, unakuwa mstari wa mkusanyiko wa mwaka. Kwa sasa, kuna njia kuu tatu za kuendesha gari: aina ya mnyororo, aina ya ukanda wa synchronous ands crew type :

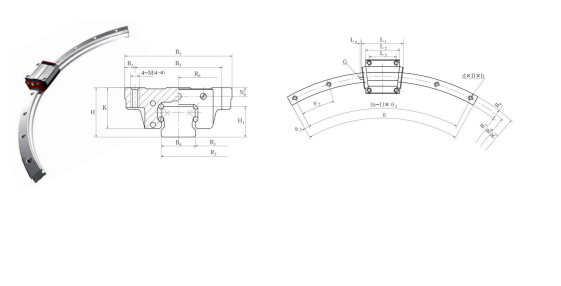

| Model | Ukubwa wa reli ya mwongozo | Ukubwa wa kitelezi | Ukubwa wa kikombe cha mafuta | ||||||||||

| H | B1 | B2 | B3 | K | L1 | L2 | L3 | M | Ф | L4 | G | N | |

| YCR16/168AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR16/228AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR16/300AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR16/390AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | MS | 4.5 | 7 | M4 | 4 |

| YCR25/230AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/400AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | MB | 7 | 11 | M6 | 6 |

| YCR25/500AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/750AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/1000AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR35/600AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/800AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/1000AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/1300AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| Mwongozo bwana | Pembe ya chini ya mwisho | Imekadiriwa mzigo mkubwa | Imekadiriwa mzigo tuli | Muda tuli uliokadiriwa | Slaidi kilo moja | Rall uzito Kg/m | Model | |||||||||

| B4 | H1 | daDuh | Θ | RΘ | R1 | R2 | Θm | Θ1 | C (MN) | (KN) | MA (Nm) | Mb (N·m) | Mc (Nm) | |||

| 16 | 15 | 4.5x7.5x5.3 | 15 ° | 168 | 160 | 176 | 160 ° | 3 ° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | YCR16/16BAA(AB) |

| 16 | 15 | 45x7.5x5.3 | 15 ° | 228 | 220 | 236 | 160 ° | 3 ° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 15 | YCR:16/228AA(AB) |

| 16 | 15 | 45x7.5x5.3 | 15 ° | 300 | 292 | 30g | 75 ° | 2 ° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | VCR16/30GAA(AB) |

| 16 | 15 | 4.5x7.5x5.3 | 15 | 390 | 382 | 398 | 65 ° | 2 ° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | YCR 16/39GAA(AB) |

| 23 | 22 | 7x11x9 | 15 ° | 230 | 218.5 | 241.5 | 160 ° | 3 ° | 16.8 | 21.5 | 142.2 | 142.2 | 233.5 | 0.59 | 3.3 | YCR25/23GAA(AB) |

| 23 | 22 | 7x11x9 | 10 ° | 400 | 388.5 | 411.5 | 60 ° | 2 ° | 16.8 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 3.3 | YCR25/40GAA(AB) |

| 23 | 22 | 7x11x | 7 ° | 500 | 488.5 | 511.5 | 60 ° | 2 ° | 168 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 3.3 | YCR25/SOGAA(AB) |

| 23 | 22 | 7x11x9 | 5* | 750 | 738.5 | 751.5 | 35 ° | 2 ° | 16.8 | 21.5 | 142.2 | 142.2 | 233.5 | 0.99 | 3.3 | YCR25/75GAA(AB) |

| 23 | 22 | 7x11x | 4 ° | 10:00 | 988.5 | 1011.5 | 28 ° | 2 ° | 16.8 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 33 | YCR25/1000A.A(AB) |

| 34 | 29 | 9x14x12 | 9" | 600 | 583 | 617 | 60 ° | 2 ° | 3497 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | YCR 3S/SOGAA(AB) |

| 34 | 29 | 9x14x12 | 5.5 | 800 | 783 | 817 | 35 ° | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | VCR 35/BOGAA(AB) |

| 34 | 29 | 9x14x12 | 5 ° | 1000 | 983 | 1017 | 28 * | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 65 | YCR3S/1000AA(AB) |

| 34 | 29 | 9x14x12 | 3.5 | 1300 | 1283 | 1317 | 22 ° | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | YCR35/1300AA(AB) |

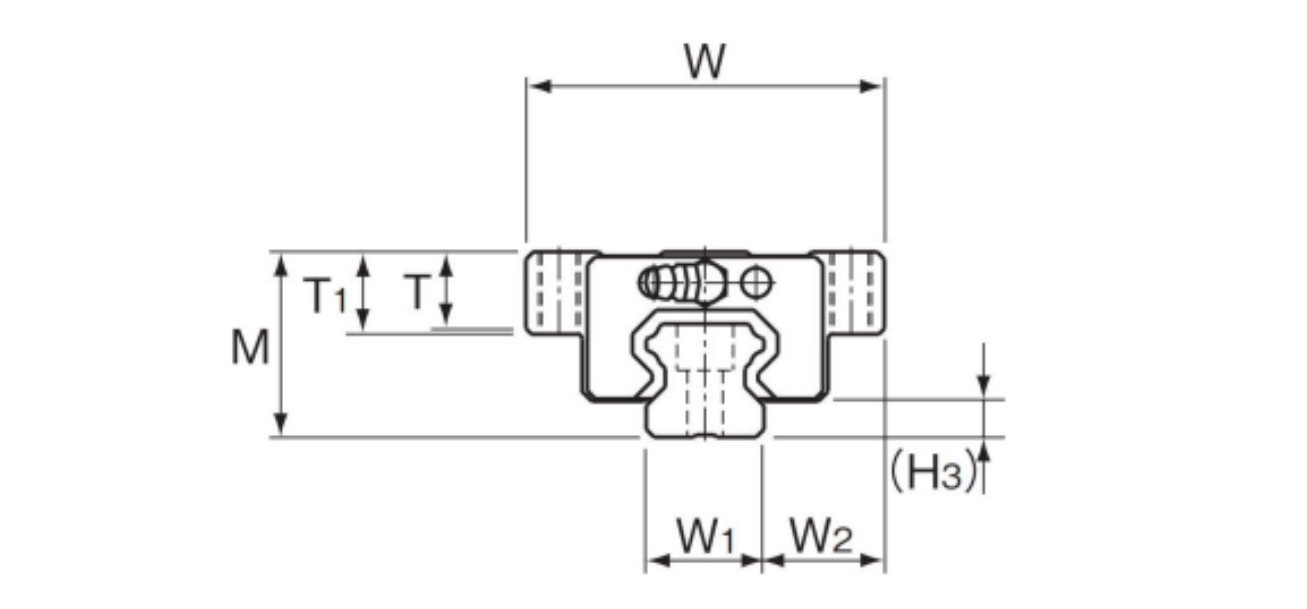

| Model No | Vipimo vya nje | Vipimo vya kuzuia LM | H3 | ||||||||||

| Urefu M | Upana W | Urefu L | B | C | S | L1 | T | T1 | N | E | Paka Nipple mafuta | ||

| YCR15A+60/150R | 24 | 47 | 54.5 | 38 | 24 | M5 | 38.8 | 10.3 | 11 | 45 | 5.5 | PB1021B | 4.8 |

| YCR15A+60/300R | 55.5 | 28 | |||||||||||

| YCR15A+60/400R | 55.8 | 28 | |||||||||||

| YCR25A+60/500R | 36 | 70 | 81.6 | 57 | 45 | MB | 59.5 | 149 | 16 | 6 | 12 | B-M6F | 7 |

| YCR25A+60/750R | 82.3 | ||||||||||||

| YCR25A+60/1000R | 82.5 | ||||||||||||

| YCR35A+60/600R | 48 | 100 | 107.2 | 82 | 58 | M10 | 80.4 | 19.9 | 21 | 8 | 12 | B-M6F | 8.5 |

| YCR35A+60/800R | 107.5 | ||||||||||||

| YCR35A+60/1000R | 108.2 | ||||||||||||

| YCR35A+60/1300R | 108.5 | ||||||||||||

| YCR45A+60/800R | 60 | 120 | 136.7 | 100 | 70 | M12 | 98 | 239 | 25 | 10 | 16 | B-PT1/8 | 11.5 |

| YCR45A+60/1000R | 137.3 | ||||||||||||

| YCR45A+60/1200R | 137.3 | ||||||||||||

| YCR45A+60/1600R | 138 | ||||||||||||

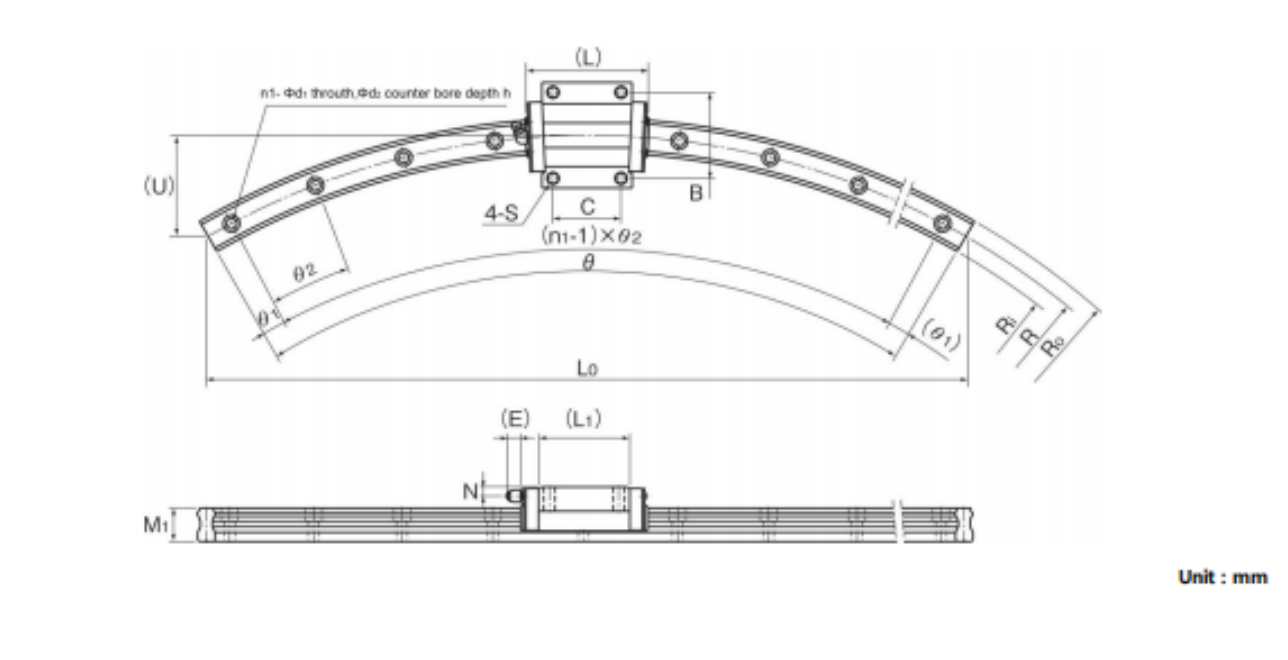

| Vipimo vya reli ya LM | Ukadiriaji wa msingi wa mzigo | Muda tuli unaoruhusiwa kN·m | Misa | ||||||||||||||||||

| R | RO | Ri | LO | U | Upana W1 | W2 | Urefu M1 | d1xd2xh | m1 | Θ° | Θ° | Θ2 | kN | CO kN | MA | MB 0 | MC 6 | LM Zuia kilo | LM Ral kg/m | ||

| 1 Kizuizi | Vitalu Mbili | 1 Kizuizi | Vitalu Mbili | 1 Kizuizi | |||||||||||||||||

| 150 | 157.5 | 142.5 | 150 | 20.1 | 15 | 16 | 15 | 4.5x7.5x5.3 | 3 | 7 | 23 | 6.66 | 10.8 | 0.0805 | 0.457 | 0.080 5 | 0.457 | 0.084 4 | 0.2 | 1.5 | |

| 300 | 307.5 | 2925 | 300 | 40 | 5 | 6 | 12 | 8.33 | 13.5 | ||||||||||||

| 400 | 407.5 | 392.5 | 400 | 54 | 7 | 3 | 9 | 8.33 | 13.5 | ||||||||||||

| 500 | 511.5 | 488.5 | 500 | 67 | 23 | 23.5 | 22 | 7x11x9 | 9 | 2 | 7 | 19.9 | 344 | 0.307 | 1.71 0 | .307 | 1.71 | 0.344 | 0.59 | 3.3 | |

| 750 | 761.5 | 738.5 | 750 | 100 | 12 | 2.5 | 5 | ||||||||||||||

| 1000 | 1011.5 | 988.5 | 1000 | 134 | 15 | 2 | 4 | ||||||||||||||

| 600 | 617 | 583 | 600 | 80 | 34 | 33 | 29 | 9x14x12 | 7 | 3 | 9 | 37.3 | 61.1 | 0.782 | 3.93 0 | .782 | 3.93 | 0.905 | 1.6 | 6.6 | |

| 800 | 817 | 793 | 800 | 107 | 11 | 2.5 | 5.5 | ||||||||||||||

| 1000 | 1017 | 983 | 1000 | 134 | 12 | 2.5 | 5 | ||||||||||||||

| 1300 | 1317 | 1283 | 1300 | 174 | 17 | 2 | 3.5 | ||||||||||||||

| 800 | 822.5 | 777.5 | 800 | 107 | 45 | 37.5 | 38 | 14x20x17 | 8 | 60 | 2 | 8 | 60 | 95.6 | 1.42 | 7.92 | 1.42 | 7.92 | 1.83 | 2.8 | 11.0 |

| 1000 | 1022.5 | 977.5 | 1000 | 134 | 10 | 3 | 6 | ||||||||||||||

| 12.00 | 1222.5 | 1177.5 | 1200 | 161 | 12 | 2.5 | 5 | ||||||||||||||

| 1600 | 1622.5 | 1577.5 | 1600 | 214 | 15 | 2 | 4 | ||||||||||||||

Hakimiliki © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd Haki Zote Zimehifadhiwa